The Engineering Value of Cylindrical Thick Film Resistors by Cermet Resistronics

The Engineering Value of Cylindrical Thick Film Resistors by Cermet Resistronics

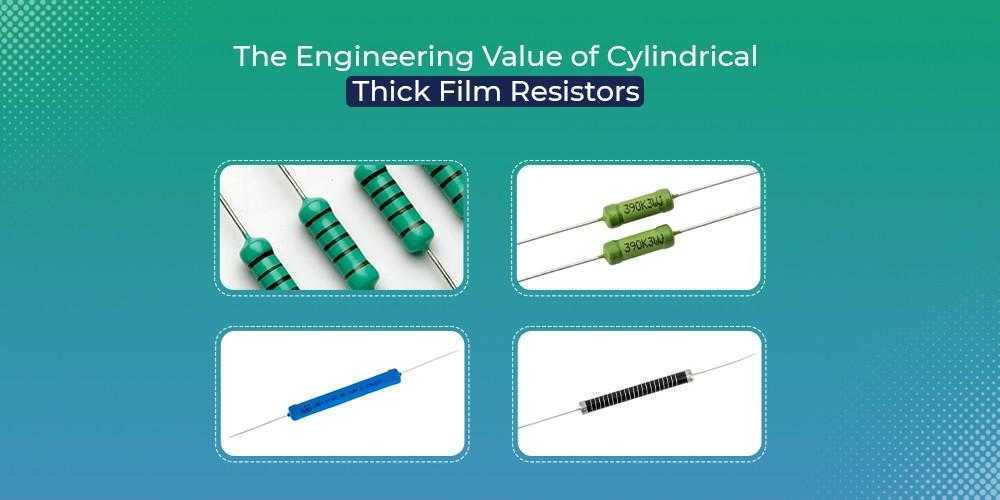

High-performance resistors are the backbone of modern power electronics, managing everything from industrial motor control to high-voltage capacitor discharge. Cermet Resistronics provides specialized Cylindrical Thick Film Resistors that handle up to 200 Giga Ohms and 25KV, offering unparalleled stability and protection in harsh industrial environments. This blog explores the technical advantages of these components and how they maintain system integrity.

How do cylindrical thick film resistors improve high-voltage system reliability?

These resistors offer superior voltage withstanding and thermal dissipation capabilities, ensuring that electrical circuits remain stable and protected against extreme voltage spikes and environmental stressors.

The Evolution of Resistance: Understanding Cylindrical Thick Film Resistors

In the complex world of electrical engineering, the stability of a circuit often depends on the quality of its passive components. Among these, Cylindrical Thick Film Resistors have become indispensable for applications that require high power handling and extreme voltage tolerance. Unlike standard surface-mount components, these cylindrical variants are designed to manage heat and electrical stress more effectively, making them a preferred choice for heavy-duty industrial systems.

At Cermet Resistronics, we have spent over 34 years perfecting the manufacturing process for these components. With a foundation built on 60 years of research and development, our approach focuses on reliability and precision. Based in Pune, India, our manufacturing facility operates with a dedicated team, ensuring that every resistor produced meets international standards of excellence.

The Technical Superiority of Metal Glaze Resistors

One of the most robust categories in our portfolio is the CMGR series, commonly known as Metal Glaze resistors. These components are crafted by applying metal glaze elements onto a high-quality ceramic substrate. The terminal is typically a tinned copper wire, and the entire assembly is protected by a specialized epoxy coating.

The primary advantage of Metal Glaze resistors is their ability to handle massive ohmic values. While standard resistors might fail under extreme loads, these units can reach values up to 200 Giga Ohms. They are particularly effective in high-voltage environments, withstanding up to 25KV and surge voltages as high as 50KV. This makes them ideal for:

- X-ray and laser equipment, where high-voltage stability is mandatory.

- Precision instrumentation requiring low noise and high accuracy.

- Industrial power supplies that face frequent voltage fluctuations.

The 2% stability rating and available tolerances of 1%, 2%, and 5% ensure that engineers can design circuits with confidence, knowing the resistance will not drift significantly over time.

Why Choose Thick Film Metal Oxide Resistors?

For applications where size and heat management are the primary concerns, Thick Film Metal Oxide Resistors provide an excellent solution. Our CSK and CVH series are designed to pack high performance into a compact footprint. These resistors utilize a metal oxide film that is thermo-chemically bonded to a high-heat conductive ceramic core.

The resulting component is small but mighty. Thick Film Metal Oxide Resistors are known for:

- Exceptional electrical and mechanical performance.

- High heat dissipation, which prevents the component from overheating in tight enclosures.

- Resistance to high humidity, making them suitable for outdoor or tropical industrial environments.

- Low noise levels are critical for signal integrity in communication devices.

In many modern systems, such as BLDC motor controls, these resistors provide the necessary current limiting without introducing significant inductance. We offer both inductive and non-inductive versions to suit specific circuit requirements.

Specialized Protection: Thick Film Metal oxide resistors- Unlacquered

In certain high-voltage applications, particularly those involving capacitor discharge, standard coatings can sometimes lead to complications. This is where Thick Film Metal oxide resistors- Unlacquered (our CUL series) become the optimal choice. These are developed using indigenous technology and are a first in the country.

The CUL series features a glass-based thick metal oxide film that is fired at a staggering 850 degrees Celsius. This high-temperature firing creates a scratch-proof film that is incredibly stable. Because they are unlacquered, these resistors do not react with or contaminate capacitor oil. This makes Thick Film Metal oxide resistors- Unlacquered the most reliable option for:

- H.T. capacitor discharge applications.

- High-stability circuits where chemical contamination must be avoided.

- Environments where mechanical scratch resistance is needed during assembly.

By removing the lacquer coating, we provide a direct heat dissipation path and eliminate the risk of outgassing or chemical reactions in oil-filled transformers and capacitors.

Industrial Applications and the Cermet Advantage

The versatility of Cylindrical Thick Film Resistors allows them to be used across a vast array of sectors. From the Indian Railways to global telecommunications providers, these components are quiet workers ensuring system longevity.

- Automotive and BLDC Motors: As the world shifts toward electric mobility, the demand for reliable motor controllers increases. Our resistors help manage the current flow in BLDC motors, ensuring smooth operation.

- Railways and Transportation: High-vibration environments require components with superior mechanical strength. The cylindrical design and robust ceramic cores of our resistors provide the necessary durability.

- Power Electronics: In LT and HT switchgear, the ability to withstand surges is non-negotiable. Our Metal Glaze resistors are specifically tested to survive these spikes.

Cermet Resistronics is not just a manufacturer; we are a solution provider. Our facility is 100% solar-powered, reflecting our commitment to sustainable manufacturing. We utilize a system-oriented approach with end-to-end ERP integration and lean manufacturing practices to ensure that every order, whether for domestic or international markets, is delivered with precision.

Conclusion: Selecting the Right Component

Choosing between Metal Glaze resistors and various types of Thick Film Metal Oxide Resistors depends on your specific voltage, thermal, and environmental needs. Whether you require the extreme ohmic range of the CMGR series or the specialized oil-compatibility of Thick Film Metal oxide resistors- Unlacquered, Cermet Resistronics has the expertise to support your project.

By focusing on high-quality materials and rigorous testing, we ensure that our Cylindrical Thick Film Resistors offer the longevity and performance required for the next generation of industrial technology. If you are looking to improve the reliability of your power systems, these advanced resistor technologies are the key to a stable and efficient future.